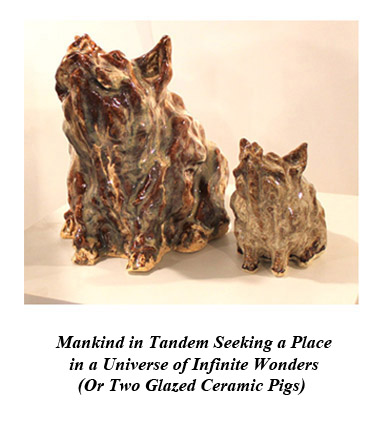

Mankind in Tandem Seeking His Place in a Universe of Infinite Wonders

(Or Two Glazed Ceramic Pigs)

Ceramics? Pah! Trinkets, mantle piece figurines, cups and saucers, pots and pans! A "craft" not an art, and a fall back if you can't think of a present to give someone you don't like.

Au contraire, mes amis, as Pablo Picasso might have said. As you can see here, ceramics can be the highest art of all. No wonder Pablo himself began to study ceramics, and he even met his second wife (and umpteenth girlfriend) in a pottery factory where he did his work.

As with most somewhat involved arts - like printmaking or bronze casting - preparing ceramics requires supervised training; it not a "teach yourself" type craft. Not only does it require specialized (and expensive) equipment (like kilns), but there are lots of subtleties in the preparation of the pieces that can really only be taught in a classroom or workshop. For instance, when you have a piece "fired", you don't want the glaze to touch the floor of the kiln. If you do, then you'll find yourself with a nice ceramic piece stuck to the kiln floor, and the operators of the kiln will express displeasure.

All right. Just what the heck is a "ceramic" and a "glaze"? Well, if you look up the word "ceramic", the definition can range from vaguely general, like "a material deriving from common raw materials", to the more specific "any of the common hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing a nonmetallic mineral, such as clay, at a high temperature". Either definition is rather vague and shows us that ceramic materials are defined largely by properties. After all, when the industry was founded maybe 5000 years ago people didn't even know atoms existed (there was doubt on that point up until the 20th century) so the Sumerians and Egyptians couldn't really tell you much about the exact chemical composition of what they were making.

We, being conservative, will stick with the more traditional definition. A ceramic is a clay - that is an inorganic mineral that adsorbs large amounts of water and achieves a plastic consistency that can be modeled. But it is not a ceramic until it has been fired - that is heated - to remove, not just the water you have added, but the chemically bound water as well. The removal of the bound water produces changes in the molecular structure that produces a material that can - literally - last forever.

And what is a clay? Well, as Gertrude Stein (whoever she was) might have said, a clay is a clay is a clay. Chemically clays are mostly oxides of silicon and aluminum with a number of other elements - potassium, sodium, calcium, and other stuff - present as cations, that is positively charged atoms that neutralize the negatively charged anions where you find the silicon and aluminum. But not all silicon and aluminum oxides are clays, by any means. Sand is silicon dioxide, and ruby and sapphire are mostly aluminum oxide. But none of these minerals are clays. Clays tend to have layered structures where water can fit in and push the layers apart. Some clays, like montmorillonites, absorb so much they expand many times their original volume. Others like kaolin (common in ceramics) don't swell that much. Generally non-swelling clays are preferred in ceramics since you don't want to have them shrinking too much as they dry.

In short, anything where adding a liquid forms a "plastic" material that can be shaped and modeled can be called a clay. So there are water clays, oil clays, and - a more modern invention - polymer clays. But still for ceramics you work with water based clays which are really what we mean by clay. Even after they absorb all the water they can hold, you can still add more water to produce a "slip" which pours like thin cream although eventually the clay will usually settle out.

Once you have modeled the sculptures - in this case the pigs - you first must dry them in air. You have to dry them carefully and slowly to prevent cracking. Oddly enough - like in drying cement - you can control the drying by occasionally spraying the surface with water. Air drying can easily take a week or two even for small pieces, much longer for larger ones.

[Note: Lest structural engineers go into spittle flinging diatribes and haughtily point out that "drying" of cement is not drying like a clay, CooperToons is aware of that. When cement solidifies it "sets" and the water you add is still present, bound in the cement. Working with cement is similar to what happens when you make plaster casts which also solidify when the water incorporates itself into the structure of the gypsum. But drying of clay is just that - the water is lost to produce the solid.]

Since when clay dries, you do actually lose water, you need to make sure that the thickness of the clay walls are uniform - which isn't always easy for statues that have different sized features. If a piece is fired and the parts are too thick, they not only can crack (drying shrinks all clays to some extent) but trapped water can also make the piece explode in the kiln. Again, if this happens, the kiln operators will voice - as we say - displeasure.

So ceramic pieces are usually hollow. You either make them hollow or you can make them solid and then hollow them out. The hollowing out is also a bit tricky since it has to be done at a stage where the clay has dried to what is called "leather". At the leather stage, the clay is firm and can be picked up with care, but still has a lot of water. To hollow out the statue you then cut it in at least two pieces and carve the innards out. You then put the two parts back together by scoring the edges with a knife, painting on some "slip", and then carefully fitting the parts back together. The cutting, hollowing, and reassembling are - like much else discussed here - best learned from an experienced teacher.

Oddly enough, at the leather stage, the clay is less fragile than when fully air dried. Also a leather stage statue can be easily repaired but if you break an air dried clay putting it back together is a formidable task. The fragility is due to the fact an air dried piece is really just a bunch of clay particles held together by adhesion and the particles still have water bound to - or more accurately, coordinated - into the minerals. Air dried clay is rather crumbly and can still reabsorb water. If you leave a non-fired clay sculpture sitting outside in the rain, you'll end up with a lump of wet clay. So if you want a permanent statue, that's when you put it in the kiln for firing.

When you fire a ceramic, the remaining water is driven off, and the molecular structure changes so water cannot recoordinate. Although a fired piece can still break, the actual material itself is as strong as marble. Oddly enough, some fired clays remain porous and they can still physically absorb water. But they can hold together. Some wine coolers are made from porous clays that you soak in water, and as the water slowly evaporates, the bottle of wine keeps cool.

Probably ceramics were discovered by some caveman who made a sun-dried cup to hold his mammoth milk and accidentally dropped it in a fire. When he retrieved the cup, he found it was much harder than before. Then somewhere along the line an Ancient Egyptian found if he made a fire on a dry like bed with a lot of natron - that is a mixture of sodium carbonate, sodium sulfate, and sodium chloride - the sand melted and formed glass. Then someone figured that by putting natron and sand on your ceramic (sounds like a euphemism, doesn't it?), it came out of the kiln with a nice shiny glass surface. The shiny surface not only looked nice, but the piece now would not absorb water, even physically. So the glazed ceramic was better for holding liquids. You could also add colored minerals to the glaze, and with the right mixtures you could make all sorts of nice decorated pots, vases, and statues, thank you. We'll talk more about the glazes below.

How hot do you heat a ceramic to fire it? Well, a couple of thousand degrees Fahrenheit is the approximate answer (ceramicists usually think in degrees Fahrenheit, rather than centigrade). But it's not really a temperature per se but the amount of heat absorbed within a given time. Although today there are programmable kilns which carefully control the temperature and rate of heating, in the olden days - and still today - the pieces are fired to what is called a certain "cone" value.

A pryometric cone is just that. It's a small ceramic cone that is placed in the kiln and fired with the pieces. During a firing, the traditional kiln master would keep an eye on the cone - the kilns had viewing ports - and the goal is to use just the right time and temperature so that the cone will begin to melt and lean over 90 degrees. If the cone doesn't lean enough, it wasn't fired enough and if it leans too much you've overfired the piece. The composition of the cones are different depending on what what ceramic you are firing. You'll hear things like something was "fired to Cone 6" or "fired to Cone 10". There are correlations of time and temperature with the cone values, but they vary with the type of kiln and its configuration and size. So even today you still stick the proper cone in the kiln to make sure the kiln is working right. These pigs were fired to Cone 6.

Ceramics are commonly fired more than once. The first firing - which is designed to remove the water and convert the clay to its waterproof state - produces what is termed "bisqueware". The bisque firing is usually at a lower temperature than subsequent firings and the ceramic isn't as strong.

Finally, to the popular mind what makes a ceramic a ceramic rather than just a clay figure (like terra cotta) is the glaze. As we mentioned above, a glaze is simply a coating of glass which makes the figure nice, shiny, and usually colorful. The glaze also helps fill in gaps and grooves and smooths out bumps (a very smooth surface can be created in unfired clay, but it isn't easy). Also clay itself remains porous and has at best a "matte" finish. Glaze also strengthens the figure. Of course, being glass, a glaze can chip and break (as can the clay itself), but fired ceramics will last indefinitely if treated with care.

From the operational standpoint, a glaze is a suspension of certain minerals in water that is coated onto the bisqueware. The multiple color effect on the pigs is caused by using two glazes one after the other. The glaze for the Big Pig was by pouring the glaze suspension over the figure (it's about 14 inches tall) and the Little Pig was dipped. The first glaze - the brown color - was added first and allowed to air dry - that takes only a few minutes, followed by the white glaze.

You'll also note the glaze thins out at the base of the statues. That's because, as we mentioned above, that you don't want the glaze melting and fusing the statue to the floor of the kiln. When the Little Pig was dipped it was held in a way that a small strip at the base was not covered. The Big Pig had a wax "resist" painted as a band along the bottom edge which kept the glaze from adhering to the surface. The wax resist is specially formulated to where if it is brushed on anywhere the glaze will not stick. So you have to be careful not to splash the resist where you do want the glaze to go.

You can buy glazes from some art supply companies, but in most ceramic shops the glazes are tailor made, and the names are also specific to the shop. They don't really tell you what is in the glaze and some formulations are proprietary. But what you will have are buckets or vats of the minerals suspended in water which after a good stirring, you add to the surface of the piece. For the record, these pigs were both glazed using the same same batches of glaze. First, the pigs were coated with "Ben's Wheatberry" followed by a coat of "Bobbi's White". Alas, neither Ben nor Bobbi were around to let us know what was in them. It takes an experienced ceramicist to know what a glaze will look like beforehand - and sometimes even they are surprised.

If you look at the composition of a glaze, it appears formidable, and you wonder how the heck can you mix them and get the same batch time and again. Fortunately, you may not have that many individual things to mix, the various minerals themselves mixtures of minerals. In addition to the water a glaze suspension contains the silica (ergo, very fine sand), some colorants, and a mineral that serves as a "flux". The flux is needed to lower the melting point of the silica so it will melt at a more modest temperature like 2300 degrees Fahrenheit rather than the "normal" 3000 degrees. But if you tried to glaze a ceramic just with silica, you would have to heat the statue up so high the clay itself might deform or even melt. That's why you add the flux.

The sharp guys and gals may ask, how ("why" is more a philosophical question) the flux lowers the melting temperature of the sand. Well, briefly the flux is an impurity, and as everyone knows, impurities lower the melting points of crystalline solids. Of course, what we just said does not answer the question. All we said was you make something melt at a lower temperature by adding something that lowers the melting temperature. So the more scientifically minded ceramic students may want to know what is actually going on in this most scientific of the visual arts.

Briefly and a bit vaguely, when you heat a crystal, you make the molecules vibrate more and more. As heating continues, eventually the molecules break away from the solid and begin moving around. At that point you are at the melting point, and if you hover at that temperature or go higher, then eventually you will make everything a liquid.

For a bit more elaboration, picture packing a bunch of ball bearings in a pan on some kind of vibrating table. Turn on the motor to a low setting, the bearings will vibrate too but not actually move. Increase the vibration - which is like increasing the temperature - and eventually the ball bearings will start bouncing around. What you've done is "melted" the crystalline solid.

Now we can conduct a thought experiment (which means we aren't sure if it really works or not). First put some other bearings of different sizes and shapes - maybe cones or cubes - on top of the original bearings. Then if you turn on the motor, you'll can see how the smaller bearings would start to move about first. That is they melt first. Then as you heat them up they would start bouncing around on top and then wedge between and help break away the heavier bearings. Then if you shut off the motor the bearings will stop moving - "freeze" - in a random orientation which is what you have in a glass.

So you see the flux helps 1) lower the melting temperature of the crystals and 2) inhibits their crystallization. This is shown diagrammatically in a separate window if you click here or click on the image at the right.

That's pretty much what a real flux does. Fluxes - sodium carbonate, barium oxide, lead oxide - melt around 1500 to 2000 degrees Fahrenheit - and become liquid. They then start interacting with the silica and help break it up - more or less, they dissolve the silica. When the liquid cools, the mixture of the fluxes, silica, colorants, and who knows what else, solidifies as a non-crystalline solid. And you get the nice shiny glaze.

The chemistry of impurities is still a tough topic and any answers you find in elementary texts or on the Fount of All Knowledge are a combination of empiricism, hand waving, and sort of giving an explanation. Shoot, it wasn't until 2008 that scientists actually were able to really look at the detailed molecular and atomic interactions to tell us why salt melts ice, for crying out loud! So don't feel bad if the chemistry of ceramics and glazing seem hard going.

References

"The effect of salt on the melting of ice: A molecular dynamics simulation", Jun Soo Kim and Arun Yethiraja, Journal of Chemical Physics, Vol. 129, 124504 (2008). This article reports on using computer simulations to see how salt interacts with ice using molecular dynamics. Molecular dynamics is a method using empirical equations to simulate molecular and atomic interactions and watch how the molecules move around. Using empirical equations is much faster than trying to use ab initio quantum or molecular orbital theory. So you can work with large assemblages of molecules. The actual empirical equations, though, sometimes are derived from quantum mechanics.

Despite what you hear from the nattering nabobs of negativism who pooh-pooh quantum mechanics, many quantum calculations are getting as good as experiment (and sometimes better). Somethings you think some people believe all theoretical work stopped in 1965. But what really turned the corner on quantum calculations into something really useful was when the computer age met density functional theory in the 1980's based on the work of Walter Kohn. We're not sure what Professor Kohn would think about his Nobel prize winning research being referenced on a web site about glazed ceramic pigs. Hopefully he would not mind.

Caveman Chemistry: 28 Projects, from the Creation of Fire to the Production of Plastics, Kevin M. Dunn, Universal Publishers (2003). Very nice book - although it's not totally caveman chemistry - on the origins of many everyday and taken for granted products and processes. A good introduction to glazes in a very intelligible manner.